Bend Steel With Your Hands sets the stage for this enthralling narrative, offering readers a glimpse into the fascinating world of hand-bending steel. From its historical roots to modern applications, we’ll explore the art and craft of shaping metal with your own two hands. This journey delves into the tools, techniques, and safety precautions required to master this challenging yet rewarding skill.

We’ll cover everything from selecting the right steel to understanding the principles of mechanics involved in bending. Learn about various bending methods, the necessary safety equipment, and troubleshooting common problems. Finally, we’ll showcase practical project examples to inspire your own creative endeavors.

Introduction to Bending Steel by Hand

Hand-bending steel, a time-honored craft, involves shaping steel using manual tools and techniques. This method, while seemingly simple, has a rich history and continues to play a vital role in various industries. From creating intricate architectural elements to shaping simple components, the skill of hand-bending steel remains a valuable asset.Historically, hand-bending steel was a crucial process for blacksmiths and metalworkers.

Early methods relied on simple tools and a deep understanding of the material’s properties. This knowledge was passed down through generations, evolving alongside advancements in metallurgy and tool design. Today, hand-bending is still practiced, particularly in situations requiring customized shapes or small-scale production.

Common Types of Steel Bent by Hand

Various types of steel are suitable for hand-bending, depending on the application and desired properties. The choice is often dictated by factors like strength, ductility, and ease of forming.

- Mild steel is a popular choice for its relative softness and malleability. Its relatively low yield strength makes it suitable for simple shapes and bends, making it an excellent starting material for beginners.

- Stainless steel, while harder to bend than mild steel, can be hand-bent if the appropriate techniques and tools are used. Its corrosion resistance makes it useful for outdoor applications.

- Alloy steels, possessing varying strengths and ductilities, can be hand-bent, but the specific alloy composition influences the difficulty of the bending process.

Applications of Hand-Bending Steel

Hand-bending steel finds use in a diverse range of applications, ranging from small-scale projects to larger-scale structural components.

- Architectural details, like decorative brackets and supports, often require custom shapes that are difficult or impossible to achieve using automated methods. Hand-bending provides the necessary precision and flexibility.

- Small-scale manufacturing, where individual pieces are needed in relatively small quantities, often benefits from hand-bending. The flexibility allows for customized designs and unique aesthetics.

- Custom fabrication projects, requiring non-standard shapes or intricate designs, are frequently completed using hand-bending techniques. This method allows for creative control and precision.

Comparison of Hand-Bending vs. Other Methods

Hand-bending steel presents distinct advantages and disadvantages when compared to other bending techniques.

| Feature | Hand-Bending | Machine Bending |

|---|---|---|

| Cost | Generally lower for small-scale projects | Lower cost for high-volume production |

| Precision | High degree of customization | High precision achievable with proper setup |

| Speed | Relatively slow for large quantities | Fast for high-volume production |

| Material Use | Less material waste (if done correctly) | Potentially more material waste if not planned effectively |

| Complexity | Requires skill and experience | Requires knowledge of equipment operation |

| Scale | Ideal for small-scale or customized jobs | Ideal for large-scale or repetitive jobs |

Tools and Techniques for Bending Steel

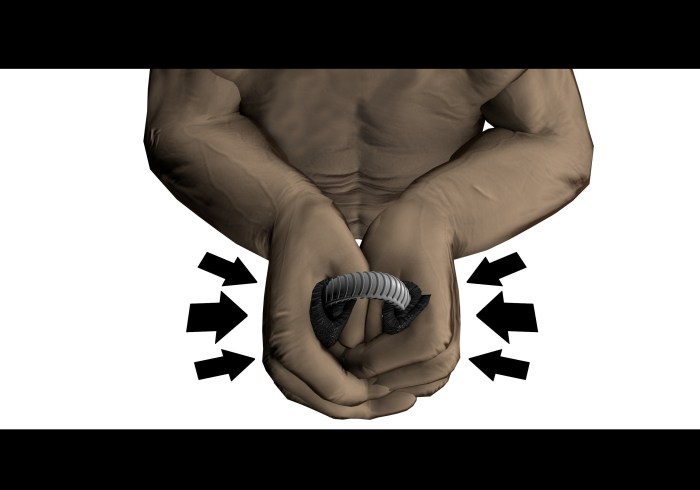

Hand-bending steel, while demanding, offers a unique way to shape metal. It’s a skill that requires precision, understanding of materials, and careful consideration of safety. This process, from initial preparation to final shaping, demands attention to detail and a familiarity with the various tools and techniques. This section delves into the essential tools and proven methods for bending steel by hand.

Essential Tools for Hand-Bending Steel

The process of hand-bending steel relies on a range of tools. Choosing the right tools and understanding their proper use is crucial for both the quality of the bend and the safety of the operator. Basic tools, including the appropriate hammers and presses, are essential. Specialized tools may be needed depending on the complexity of the bend.

- Hammers: Different types of hammers, from ball-peen to sledgehammers, are used for various bending tasks. The selection of the hammer depends on the thickness and type of steel being worked with.

- Bending Rolls: These tools are particularly helpful for creating uniform curves and bends in longer lengths of steel. Their design allows for consistent bends, and they are frequently used in industrial settings.

- Presses: Mechanical presses provide a controlled and consistent force for bending, ideal for creating complex shapes or when precise bends are required. Presses, often powered, can handle heavier gauge steel than hand tools.

- V-Blocks: These provide support and alignment for the steel piece during bending, preventing slippage and ensuring a controlled bend.

- Clamps: These secure the steel piece in place while bending, crucial for maintaining the integrity of the shape and preventing movement.

Techniques for Hand-Bending Steel

Several techniques are employed in hand-bending steel. Each method has its own advantages and disadvantages, and the choice depends on the type of steel, the desired shape, and the available tools.

- Hammering: This technique involves striking the steel piece with a hammer to gradually shape it into the desired curve. The direction and force of the hammer blows are critical for achieving the desired bend without causing damage or cracking.

- Pressing: This technique uses mechanical presses to apply consistent pressure to the steel, enabling the creation of precise and controlled bends. This method is particularly useful for bending thicker steel or when complex curves are required.

- Using Specialized Tools: Specialized tools, such as bending rolls, are used to shape the steel. These tools often provide a more uniform bend, and they can handle larger lengths of steel.

Safety Precautions

Working with steel, even in hand-bending operations, requires stringent safety measures. Understanding the risks and implementing protective measures is essential to avoid injuries.

| Safety Hazard | Prevention Measures |

|---|---|

| Flying debris | Wear safety glasses or a face shield, and use appropriate protective clothing. |

| Sharp edges | Use appropriate safety gloves and handle the steel with caution. |

| Burns from heat generated during hammering | Wear appropriate protective gear, and maintain a safe distance. |

| Strain from repetitive motions | Take frequent breaks and use proper lifting techniques. |

| Slips and falls | Maintain a clean and organized workspace. |

Effective and Safe Use of Tools

Proper technique is vital when using hand-bending tools. Correct handling ensures the desired outcome and prevents damage or injury.

- Hammering: Ensure the hammer head is appropriate for the steel thickness. Use controlled strikes and avoid striking the steel in an uncontrolled manner. Maintain a firm grip on the hammer.

- Presses: Follow the manufacturer’s instructions carefully for operating the press. Ensure the steel is properly positioned and secured. Never operate the press without safety guards in place.

- Bending Rolls: Ensure the steel is correctly positioned within the rolls. Use the correct procedures for engaging and disengaging the rolls.

Comparison of Bending Techniques

Different bending techniques offer various strengths and weaknesses. The choice of technique depends on the specific application and the desired outcome.

| Technique | Strengths | Weaknesses |

|---|---|---|

| Hammering | Versatile, relatively inexpensive tools, adaptable to various shapes | Can be less precise, requires experience, potentially damaging to steel if not handled correctly. |

| Pressing | Precise, consistent bends, suitable for complex shapes, faster than hammering | Requires specialized equipment, can be expensive, limited to certain shapes. |

| Specialized Tools | High precision, uniform bends, suitable for long lengths | Specialized tools can be expensive, not as versatile as hammering. |

Safety and Precautions

Hand-bending steel, while rewarding, presents inherent risks. Proper safety measures are paramount to preventing injuries and ensuring a safe working environment. Neglecting safety protocols can lead to severe consequences, ranging from minor cuts and bruises to potentially life-altering injuries. Therefore, a comprehensive understanding of the potential hazards and the necessary precautions is crucial for anyone undertaking this craft.Understanding the potential hazards associated with bending steel is critical for effective risk mitigation.

Steel’s inherent strength and the tools used for manipulation can lead to serious accidents if not handled carefully. These hazards include sharp edges, the risk of burns from heat generated during the process, and the possibility of being struck by flying debris. This understanding fuels the necessity for diligent safety practices.

Potential Risks and Hazards

Steel, in its various forms, presents several hazards. Sharp edges on raw steel can cause cuts and lacerations. The high tensile strength of steel, combined with the forces applied during bending, can lead to the steel fracturing or snapping, resulting in flying debris. Improper use of bending tools, such as excessive force or improper leverage, can lead to tool breakage and the release of hazardous materials.

Furthermore, some bending methods involve heat, posing a risk of burns. The specific risks depend heavily on the type of steel being worked with, the bending technique, and the tools being used.

Safety Equipment Requirements

A comprehensive safety equipment list is essential for mitigating risks. This list should include protective gear to safeguard against various potential hazards.

- Eye Protection: Safety glasses or a face shield are crucial to protect the eyes from flying debris, sparks, or metal shards. Welding helmets or goggles should be used if the process involves any heat or sparks. The impact resistance of the chosen eyewear is critical for safety.

- Hand Protection: Heavy-duty work gloves are essential to protect hands from cuts, abrasions, and the grip required for holding steel and tools. Leather or reinforced composite materials are preferred for their durability and ability to withstand abrasion and punctures.

- Foot Protection: Steel-toe work boots or safety shoes provide crucial protection against falling objects and impact. The robust construction of these boots prevents foot injuries.

- Hearing Protection: Some bending techniques, especially those involving hammers or impact tools, can generate significant noise. Ear plugs or muffs are recommended to protect hearing.

- Personal Protective Equipment (PPE) for Specific Tasks: Depending on the type of steel and the bending method, additional PPE may be necessary, such as aprons, respirators, or heat-resistant clothing. For example, if welding is involved, a welding suit or jacket will be required to protect against burns.

Proper Handling Procedures

Safe handling procedures are critical for preventing accidents. This involves careful attention to detail and the consistent use of proper techniques.

- Steel Handling: When handling steel plates or bars, use appropriate lifting equipment such as jacks, cranes, or specialized lifting devices. Avoid lifting heavy steel manually unless absolutely necessary. If manual lifting is unavoidable, use proper lifting techniques to prevent back injuries. Ensure the steel is secured before attempting to bend it.

- Tool Usage: Tools should be inspected for any damage before use. Ensure tools are properly maintained to maintain their functionality and avoid unexpected failures. Follow the manufacturer’s instructions for using each tool correctly, including proper torque, pressure, and technique.

- Work Area Setup: Ensure the work area is clear of obstructions and hazards. The area should be well-lit and have appropriate ventilation. Use designated areas for storing tools and materials.

Importance of Protective Gear

Protective gear is not merely a precaution but a crucial element in maintaining a safe working environment. Wearing appropriate protective gear minimizes the risk of injury and protects against the range of potential hazards associated with steel bending. It acts as a barrier between the worker and the potential dangers of the work environment. Without proper protective gear, even minor incidents can escalate into severe injuries.

Materials and Selection: Bend Steel With Your Hands

Choosing the right steel for hand-bending is crucial for success. The characteristics of the steel directly impact the ease and quality of the bending process, as well as the final product’s durability. Different steels exhibit varying degrees of malleability and strength, making informed selection essential for achieving desired results. Understanding these properties will guide you towards achieving precise bends and prevent material failure.

Types of Steel for Hand-Bending

Various types of steel are suitable for hand-bending, each with unique properties. Understanding these differences is key to selecting the optimal material for your project. Common choices include mild steel, spring steel, and stainless steel, each possessing varying degrees of ductility and strength.

Properties Affecting Hand-Bending

The key properties to consider when selecting steel for hand-bending are malleability and ductility. Malleability refers to the material’s ability to be hammered or shaped without fracturing, while ductility describes its ability to be drawn or stretched into thin wires without breaking. These properties directly influence how easily the steel can be bent and the resulting shape’s integrity.

Ever wondered how to bend steel with your bare hands? It’s a fascinating skill, requiring immense strength and precision. It’s a bit like the incredible challenges in games like Skyrim, where you might need to find a way to cure vampirism. For example, Cure Vampirism in Skyrim presents a whole new set of hurdles.

Ultimately, both the real-world skill of bending steel and the fictional challenges of the game highlight the power of human ingenuity and determination. I’m inspired to learn more about the real-world techniques involved in bending steel.

Material Selection Based on Application, Bend Steel With Your Hands

The desired shape and application significantly influence the choice of steel. For example, a simple, gentle curve might be achievable with mild steel, whereas a complex, precise bend might require spring steel due to its greater elasticity and recovery. The specific requirements of your project will dictate the most appropriate steel type.

Steel Characteristics for Hand-Bending

| Steel Type | Malleability | Ductility | Strength | Suitability |

|---|---|---|---|---|

| Mild Steel | High | High | Moderate | Simple bends, general applications |

| Spring Steel | Medium | Medium | High | Precise bends, applications requiring springiness |

| Stainless Steel | Medium | Medium | High | Applications requiring corrosion resistance |

This table provides a general overview of common steel types suitable for hand-bending. It highlights the varying characteristics of each type, helping you to make an informed decision.

Durability and Malleability Comparison

Mild steel is known for its high malleability, making it relatively easy to bend by hand. However, its lower strength might lead to more pronounced stretch or deformation during the bending process, potentially affecting the final product’s integrity. Spring steel, with its higher strength and elasticity, allows for more precise bends and greater durability, but it’s more challenging to work with due to its slightly lower malleability.

Stainless steel, often used in applications requiring corrosion resistance, falls in between these two, offering a good balance of bendability and durability. The chosen steel should always align with the intended use and expected stresses.

Specific Bending Methods

Hand-bending steel, while seemingly simple, involves a deep understanding of material properties and mechanical principles. Mastering various techniques allows for the creation of intricate shapes and forms. From simple curves to complex angles, precise bending requires careful consideration of the steel’s characteristics and the tools employed.This section delves into the specific methods of hand-bending steel, detailing the procedures for achieving desired shapes, angles, and curves.

It also explores the underlying mechanics and provides step-by-step guides to help you achieve accurate bends.

Bending Techniques for Different Shapes

Understanding the properties of steel is paramount in achieving successful bends. Steel’s elasticity and yield strength determine how much force is needed and how the material will deform. Different bending techniques are suited for specific shapes, and selecting the right technique minimizes stress on the material and the tools.

- Creating Curves: A common technique for creating curves involves using a bending block and hammer. The bending block provides a stable surface, and the hammer applies controlled force to the steel. The angle and radius of the curve depend on the shape of the bending block and the amount of force applied. Practice is key to developing a feel for the appropriate force needed to achieve the desired curvature without damaging the material.

- Forming Angles: Angles are often formed using a combination of bending blocks and specialized bending tools. The specific tool used depends on the angle and the thickness of the steel. Precise measurements and careful alignment are crucial to achieve the required angle. Using a straight edge for initial alignment and ensuring consistent pressure are key to accuracy.

- Creating Complex Forms: For complex shapes, a combination of techniques is often employed. For example, a curve might be created first, and then an angle is formed from that curve. Using multiple bending blocks, or even progressively shaping the material in stages, helps achieve intricate designs.

Mechanics of Hand Bending Steel

The mechanics behind hand-bending steel involve several key principles. Understanding these principles helps in predicting the behavior of the steel during bending and ensuring the desired outcome.

The fundamental principle is that the force applied to the steel creates internal stresses. These stresses cause the steel to deform until it reaches its yield point, where permanent deformation occurs.

- Force Application: The force applied must be consistent and well-distributed to avoid localized stress concentrations. Improper force application can lead to uneven bending, breakage, or buckling.

- Material Properties: The mechanical properties of the steel, including its yield strength and ductility, significantly affect the bending process. Thicker steel requires more force and a different technique than thinner steel.

- Leverage and Torque: Employing leverage and torque effectively helps to maximize the force exerted on the steel while minimizing the effort required from the bender. Using leverage tools allows you to achieve bends that would otherwise be impossible with direct force alone.

Steps in Bending Various Shapes

Following a systematic approach for bending various shapes is crucial for achieving precision and consistency. This structured approach minimizes the risk of errors and ensures the desired outcome.

| Shape | Step-by-Step Procedure |

|---|---|

| Simple Curve | 1. Mark the desired curve on the steel. 2. Place the steel on a bending block. 3. Apply controlled force to the steel using a hammer, ensuring even pressure. 4. Check the shape and adjust as needed. |

| Right Angle | 1. Mark the desired angle on the steel. 2. Position the steel between two bending blocks. 3. Apply controlled force to bend the steel to the desired angle. 4. Check the accuracy of the angle using a straight edge. |

| Complex Shape | 1. Divide the complex shape into simpler shapes. 2. Bend each simpler shape using appropriate techniques. 3. Combine the bent shapes to create the desired complex form. 4. Ensure smooth transitions between different shapes. |

Achieving Precise Bends

Achieving precise bends requires meticulous attention to detail and the right tools. The use of measuring tools, such as calipers and rulers, is essential to accurately determine the desired bend. Maintaining consistent pressure and avoiding localized stress concentrations are also vital.

Speaking of bending things, I’ve been fascinated by the “Bend Steel With Your Hands” technique lately. It’s all about mastering control and precision, a bit like watching Kanye West, Justin Timberlake, and NSYNC, Drake, Kendrick Lamar, and 2 Chainz perform at the VMA’s here. That kind of raw, controlled power is really inspiring, and it makes me think about how much control and precision is needed in the metalworking process.

Ultimately, both are about pushing boundaries and showcasing incredible skill.

- Measuring Accuracy: Precise measurements are essential to ensure the desired shape and angle are achieved. Use accurate measuring tools and double-check measurements.

- Tool Selection: Choosing the appropriate bending tools based on the material’s thickness and the desired shape is crucial for efficient and safe bending.

- Practice and Technique: Consistent practice and a good understanding of bending techniques significantly improve the accuracy and quality of bends. Regular practice allows you to develop a feel for the force required to achieve a precise bend, leading to improved results.

Project Examples

Hand-bending steel offers a versatile way to craft a wide array of functional and decorative objects. From simple coat racks to intricate sculptures, the possibilities are limited only by your imagination and the material’s properties. This section explores diverse project examples, highlighting the design considerations, tools, techniques, and a comparison of complexity and application.

Simple Project Examples

Simple projects, often starting points for beginners, demonstrate the fundamental principles of hand-bending. These projects typically involve straightforward shapes and minimal bending operations.

- Coat Rack: A simple coat rack, crafted from a single piece of steel, requires careful measurement and bending to create uniform hooks. Design considerations include the desired hook spacing and the overall rack size. Tools like a steel ruler, marking tools, and bending hammers are necessary. Basic bending techniques, such as V-bending and U-bending, are essential.

Bend Steel With Your Hands is all about channeling raw energy, right? Well, that same kind of focused drive is inspiring the upcoming matmos to release album featuring Dan Deacon, Angel Deradoorian, and more, plus a tour! This new release seems like it’s going to be a must-listen for anyone who loves experimental soundscapes. It’s a reminder that pushing boundaries in music, like bending steel, requires a lot of passion and precision.

- Shelf Bracket: A shelf bracket exemplifies the creation of a supporting structure. Design involves determining the bracket’s dimensions and load capacity. Using a combination of bending and shaping tools, a sturdy bracket can be formed for a shelf. The precise angles and bends are crucial for stability.

Complex Project Examples

Complex projects demand a higher level of skill and precision, requiring a thorough understanding of bending techniques and material properties. These projects can involve intricate shapes, multiple bending operations, and a deeper appreciation for design considerations.

- Ornamental Gate: An ornamental gate, crafted from steel, can exhibit a variety of intricate designs. The design should include detailed patterns and potentially different bending angles for various shapes. Advanced bending tools like specialized bending dies and possibly hydraulic presses may be needed, alongside specialized bending techniques.

- Sculpture: Steel sculptures can range from simple forms to highly complex designs. Design considerations include the intended message, the material’s capabilities, and the desired aesthetic. The project requires precise bending techniques to achieve the intended form, potentially involving multiple shaping methods and potentially heat treatment after forming.

Project Comparison Table

The table below compares different project examples based on their complexity and application, highlighting the essential tools and techniques.

| Project | Complexity | Application | Key Tools | Bending Techniques |

|---|---|---|---|---|

| Coat Rack | Low | Functional | Steel ruler, marking tools, bending hammer | V-bend, U-bend |

| Shelf Bracket | Low-Medium | Functional | Steel ruler, marking tools, bending hammer, possibly a vice | V-bend, U-bend, possibly other shaping techniques |

| Ornamental Gate | Medium-High | Decorative | Steel ruler, marking tools, bending hammer, possibly specialized bending dies, potentially hydraulic press | Complex shaping techniques, possibly using a die |

| Sculpture | High | Decorative/Functional | Advanced bending tools, shaping tools, possibly specialized heat treatment equipment | Precise shaping techniques, potentially using multiple bending methods and heat treatment |

Troubleshooting and Problem Solving

Hand-bending steel, while rewarding, can present challenges. Understanding the potential problems and their causes is crucial for achieving consistent, successful bends. This section details common issues, solutions, and techniques for achieving accurate and reliable results.Effective troubleshooting involves a combination of understanding the materials, the tools, and the process itself. Careful observation and analysis of the bending process can help identify the root cause of inconsistencies, ultimately leading to more efficient and accurate work.

Common Bending Inconsistencies

Identifying the root cause of inconsistencies in steel bending is critical for achieving accurate results. Variations in bend radius, uneven thickness deformation, and material breakage can stem from several factors.

- Uneven Bend Radius: A significant contributor to inconsistent bends is an uneven bend radius. This can occur if the bending tool isn’t properly positioned or if the material isn’t consistently supported throughout the bending process. Uneven support can lead to localized stress concentrations, causing the metal to bend unevenly. For example, using a bending tool with a worn-out or damaged die can result in inconsistent bend radii.

- Uneven Thickness Deformation: Variations in material thickness can also affect the bend. Thicker sections of the material may resist bending, while thinner sections might bend too easily. This uneven deformation can lead to a final shape that’s not what was intended. Using a bending fixture to evenly distribute pressure is vital in such situations.

- Material Breakage During Bending: Steel breakage during the bending process is a serious issue. This often stems from improper material selection, insufficient support, or excessive bending force. Applying excessive force without proper support can result in fractures. Understanding the yield strength of the steel is critical in preventing breakage.

Solutions for Overcoming Bending Challenges

Addressing bending issues requires a methodical approach. A range of solutions can be applied, from adjusting tools to modifying the bending process itself.

- Adjusting Bending Tools: Ensure the bending tool is properly calibrated and that the die is in good condition. A worn-out die can cause an uneven bend radius. Regular maintenance of bending tools is critical for consistent results.

- Optimizing Support: Proper support of the material is paramount. Ensure the material is supported evenly throughout the bending process. Using bending jigs or fixtures can aid in uniform support. Using clamps to secure the material and applying pressure at multiple points are techniques to use when working with different sizes of steel. The material must be securely clamped to prevent slippage and ensure the force is applied uniformly.

- Controlling Bending Force: Applying too much force can lead to material breakage. Ensure the bending force is appropriate for the material’s thickness and strength. This is often dependent on the type of steel, its gauge, and the desired bend. Use a calibrated bending machine, or for manual methods, a calibrated force gauge. Gradually increase the bending force to observe how the material reacts to avoid unexpected breakage.

Ensuring Accurate and Consistent Bends

Precision in bending steel relies on meticulous attention to detail and the application of proper techniques.

- Preheating Materials: Preheating the steel before bending can make the metal more pliable and reduce the likelihood of breakage. This is particularly important when bending thicker or more brittle materials. Preheating reduces the material’s internal stresses, making the bending process smoother and more accurate.

- Accurate Marking and Planning: Thorough planning and accurate marking are critical. Use a measuring tool and create a template or pattern to ensure the bend is precisely aligned with the desired angle and radius. Marking and cutting the material accurately will contribute to the desired shape.

Outcome Summary

In conclusion, hand-bending steel is a powerful skill that combines artistry, precision, and a deep understanding of materials. This guide has provided a comprehensive overview of the entire process, from initial selection to final shaping. With the right tools, techniques, and safety precautions, you can transform steel into stunning pieces of art or functional objects. The journey of bending steel with your hands is one that will undoubtedly leave you with a profound appreciation for the craft.