Install a Gas Cap is crucial for vehicle safety and fuel efficiency. Proper installation prevents leaks, reduces the risk of accidents, and ensures your car runs smoothly. This guide covers everything from identifying different gas cap types to troubleshooting common problems, making the process straightforward and easy to understand.

This comprehensive guide will take you through the entire process, step-by-step. From understanding the importance of a correctly installed gas cap to the various tools and safety precautions required, you’ll be equipped to tackle this task confidently.

Introduction to Gas Cap Installation

Properly installing a gas cap is more than just a simple task; it’s a crucial step in maintaining vehicle safety and efficiency. A secure gas cap prevents fuel leaks, reduces the risk of vapor emissions, and ensures the integrity of the fuel system. Ignoring this seemingly minor detail can lead to significant problems down the road.Improper installation can create a variety of problems, from fuel loss and environmental hazards to potential safety issues.

A loose or damaged gas cap can allow fuel to spill, creating a fire hazard and polluting the environment. Furthermore, a poorly sealed cap can lead to uncontrolled fuel vapor emissions, potentially impacting air quality and contributing to smog formation.

Gas Cap Types

Different vehicle models utilize various gas cap types, each designed to meet specific safety and performance standards. Understanding the differences in gas cap types is essential for proper installation and maintenance.

| Gas Cap Type | Material | Features | Security Rating |

|---|---|---|---|

| Example Type 1 (Metal) | Metal (e.g., aluminum, steel) | Typically utilizes a threaded design for secure fastening, often with a gasket for sealing. May include a locking mechanism for added security. | High |

| Example Type 2 (Plastic) | Plastic (e.g., ABS, polypropylene) | Often lightweight and less expensive than metal caps. Some designs incorporate locking mechanisms for enhanced security. May be more susceptible to damage or deformation than metal caps. | Medium |

| Example Type 3 (Electronic/Integrated) | Combination of materials (e.g., plastic housing with an electronic sensor) | These caps often incorporate a sensor to monitor fuel level, vapor pressure, or even detect tampering. They are usually integrated with the fuel filler neck. | High |

The table above provides a general overview of common gas cap types. Each vehicle model might have specific requirements and recommendations for gas cap installation, so always consult the vehicle’s owner’s manual for detailed instructions. Specific features like locking mechanisms or integrated sensors influence the security rating of the gas cap.

Figuring out how to install a gas cap might seem mundane, but sometimes the little things in life, like ensuring your car’s gas tank is properly sealed, can be surprisingly heartwarming. Just like carefully crafting a heartfelt message, like those found in Touching Love Messages for Her , it’s important to pay attention to the details. A properly installed gas cap guarantees your car runs smoothly, much like a loving relationship is built on thoughtful consideration and care.

So, next time you’re tackling a gas cap installation, remember to be meticulous, and you’ll be rewarded with a running car.

Tools and Materials Required

Installing a gas cap correctly requires the right tools for the job. Improper tools can damage the cap or the gas tank, leading to potential leaks or other issues. This section details the essential tools and materials needed for a safe and successful installation.The following tools are crucial for a smooth and secure gas cap installation. Careful selection and proper use of these tools are essential to prevent damage to the gas cap, the gas tank, and to ensure a tight seal.

Required Tools

The installation process necessitates a few specific tools, each playing a vital role in the procedure. Carefully selecting the correct tools is essential for a successful installation.

- A suitable wrench:

- A wrench that matches the size of the gas cap’s threads is essential. Incorrect sizing can result in damage to the cap or the gas tank. The wrench should be sturdy enough to grip the cap securely without slipping, and the size of the wrench will depend on the specific type of gas cap on your vehicle.

- A screwdriver:

- A Phillips-head screwdriver is usually needed to remove or install any retaining screws that secure the gas cap to the gas tank. Using the wrong type of screwdriver can damage the cap or the tank. A sturdy screwdriver that matches the size of the screws will be necessary.

- Safety Glasses:

- Safety glasses should always be worn to protect your eyes from debris or potential sparks during the installation process. This is a crucial safety precaution.

Detailed Tool Description

Using the right tool is critical for a successful gas cap installation. The tools should be chosen based on the specific gas cap model and the vehicle’s make and model.

| Tool | Description | Purpose |

|---|---|---|

| Wrench (Appropriate Size) | A wrench designed for gripping and turning nuts and bolts. It should have a sturdy head and a comfortable handle. Ensure the wrench size precisely matches the gas cap’s threads to avoid damaging the cap or tank. | To loosen and tighten the gas cap. |

| Phillips-head Screwdriver | A screwdriver with a cross-shaped tip for turning Phillips-head screws. It should be sturdy enough to handle the screws without stripping the head or damaging the threads. | To remove or install any retaining screws securing the gas cap to the gas tank. |

| Safety Glasses | Protective eyewear designed to prevent debris or sparks from entering the eyes. They should provide adequate coverage and a secure fit. | To protect your eyes during the installation process. |

Safety Precautions: Install A Gas Cap

Installing a gas cap, while seemingly straightforward, requires careful attention to safety protocols. Ignoring these precautions can lead to significant risks, from minor injuries to potentially severe accidents. Understanding the potential hazards and taking the necessary safety steps is crucial for a safe and successful installation.Proper safety precautions are essential for minimizing risks when working with fuel systems and flammable materials.

These measures extend beyond the installation process itself and encompass the entire work environment. By implementing and adhering to these safety guidelines, individuals can significantly reduce the likelihood of accidents and maintain a safe working environment.

Pre-Installation Safety Measures

Before beginning any gas cap installation, ensure the area is safe and prepared. This includes evaluating the environment for potential hazards and taking proactive steps to mitigate those risks.

Replacing a gas cap might seem like a small task, but it’s crucial for safety and preventing leaks. Knowing how to properly install a gas cap is important. For example, did you know that understanding your online connections can be just as important as your physical ones? Take a look at how to see who you are most connected to on Facebook See Who You are Most Connected to on Facebook to gain a better perspective on your online network.

Hopefully, this helps you feel more informed and secure, and ultimately, helps you properly install your gas cap, too.

- Check for Leaks: Thoroughly inspect the fuel system for any visible leaks. This includes the fuel tank, fuel lines, and the gas cap itself. Any signs of leaks, such as drips or puddles, indicate a potential safety concern that must be addressed before proceeding with installation.

- Secure the Area: Clear the area around the fuel tank of any obstructions or materials that could pose a tripping hazard or impede access to the fuel cap. Ensure adequate lighting for visibility. This creates a safe workspace and prevents accidents.

- Ventilate the Area: Proper ventilation is paramount when working with fuel and flammable materials. Open windows and doors, or use a fan, to ensure adequate airflow and reduce the concentration of fumes in the air. This helps prevent inhalation of hazardous vapors.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses or goggles, to protect your eyes from flying debris or splashes of fuel. Gloves provide a barrier against potential skin contact with fuel or chemicals. This protects against minor injuries and long-term health risks.

Safety Precautions Related to Fuel and Flammable Materials

Handling fuel and flammable materials demands particular attention to safety. The potential for fire or explosion requires strict adherence to safety procedures.

- Fuel Storage: Ensure fuel storage containers are properly sealed and stored in a safe location away from heat sources and open flames. Store them in designated areas to prevent accidental ignition.

- Avoid Smoking: Prohibit smoking or any open flame activities in the immediate vicinity of fuel and flammable materials. A spark from a cigarette can ignite fuel vapors and cause a fire.

- Grounding: Ground all tools and equipment used in fuel system work to prevent static electricity sparks that could ignite flammable vapors. This crucial step prevents unwanted ignitions.

- Proper Handling: Use appropriate handling techniques for fuel and related materials to avoid spills or splashes. Use containers with secure lids and avoid any unnecessary movements that might lead to accidents.

Potential Hazards of Working with Gas Caps and Fuel Systems, Install a Gas Cap

Working with gas caps and fuel systems presents several potential hazards that require careful consideration. These include potential injuries, fires, and explosions.

- Fuel Burns: Contact with fuel can cause severe burns, particularly if the fuel is hot. Take precautions to avoid direct contact with hot or spilled fuel.

- Inhalation of Fumes: Fuel vapors are often harmful and can cause respiratory problems. Work in well-ventilated areas and avoid inhaling these vapors. Always wear appropriate respirators if necessary.

- Fire Hazards: Fuel and fuel systems are highly flammable. Take precautions to avoid any ignition sources. Always be aware of the potential for fire when working with these systems.

- Explosion Risks: Fuel vapors can accumulate and create explosive mixtures. Never work in confined spaces without proper ventilation and safety measures. Always have a fire extinguisher nearby in case of emergency.

Safety Checklist

A comprehensive safety checklist is essential for preventing accidents. It serves as a practical guide to ensure all safety measures are taken before and during the installation process.

- Check for leaks in the fuel system.

- Clear the work area of obstructions.

- Ensure adequate ventilation.

- Wear appropriate personal protective equipment.

- Store fuel and flammable materials safely.

- Avoid open flames and smoking.

- Ground all tools and equipment.

- Handle fuel carefully to prevent spills.

- Have a fire extinguisher readily available.

Step-by-Step Installation Procedure

Installing a gas cap might seem straightforward, but proper installation ensures safety and optimal performance. A correctly installed gas cap prevents leaks, which are a significant fire hazard. Knowing the specific procedure for your vehicle type is crucial for a secure fit and to avoid damaging the cap or the gas filler neck.

Detailed Installation Procedure

The process involves several key steps, each crucial for a successful installation. Carefully following the steps will minimize the risk of issues and ensure the cap is correctly seated. Failure to adhere to the correct procedure could lead to leakage or improper sealing, which is a serious safety concern.

Various Vehicle Types

Different vehicle models may have slightly varying installation procedures. Understanding the specifics for your vehicle type is essential. For example, some vehicles might require a specific torque setting for tightening the cap, while others may have a unique cap design.

Step-by-Step Guide

| Step | Action | Description | Image Description |

|---|---|---|---|

| Step 1 | Preparation | Ensure the area is clean and well-lit. Gather the necessary tools (e.g., wrench or socket set, if required). Check for any damage to the gas cap or the gas filler neck. | A well-lit area with a vehicle’s gas filler neck clearly visible. A hand holding a wrench is also visible. |

| Step 2 | Cap Removal (if applicable) | If the old gas cap is stuck, use the appropriate tool (e.g., wrench) to carefully remove it. Take care not to damage the filler neck. Be mindful of any security features on the cap or the filler neck. | A person carefully removing a gas cap with a wrench from a gas filler neck. The filler neck and the gas cap are shown in good condition. |

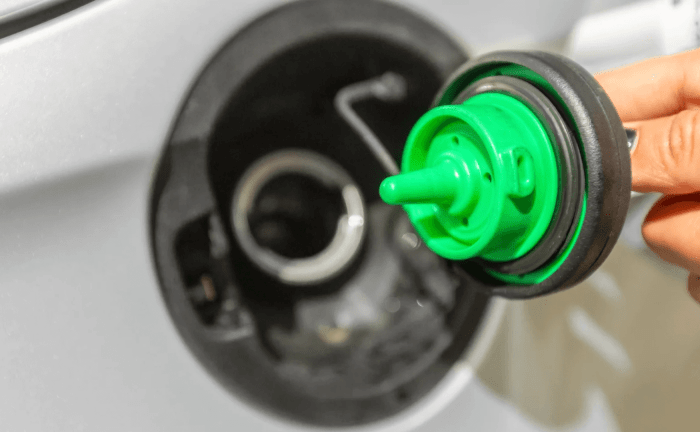

| Step 3 | Cap Placement | Position the new gas cap onto the gas filler neck. Align the cap with the filler neck ensuring proper orientation. Check the cap’s alignment for a snug fit. | A new gas cap positioned precisely on a gas filler neck. The cap is centered and aligned, ready for tightening. |

| Step 4 | Tightening | Use the appropriate tool to tighten the gas cap. Apply a firm, even pressure, but avoid over-tightening. Some gas caps have specific torque specifications. Refer to your vehicle’s owner’s manual for precise instructions. | A person using a wrench to tighten a gas cap on a gas filler neck. The wrench is being applied evenly to the cap. |

| Step 5 | Verification | After tightening, check the gas cap for a secure fit. Ensure the cap is not loose or wobbly. Try to gently push and turn the cap to confirm its stability. | A person examining a gas cap to ensure it is firmly seated and not loose or wobbly. The cap is firmly in place. |

Troubleshooting Common Issues

Sometimes, even with the best intentions and meticulous preparation, things can go awry during a gas cap installation. Understanding potential problems and their solutions can save you time and frustration. This section delves into common issues encountered during gas cap replacement, providing clear explanations of their causes and effective troubleshooting methods.

Ever wondered how to properly install a gas cap? It’s surprisingly easy, but crucial for safety. Speaking of important things, did you know that the talented Matt Berninger of the National’s is creating and starring in a TV show about his life? This fascinating project is definitely worth checking out, but before you dive into that, make sure your gas cap is securely installed.

A loose cap can lead to leaks and other issues. A quick check and a tight seal can go a long way.

Identifying Gas Cap Installation Problems

Proper gas cap installation is crucial for vehicle safety and preventing leaks. Identifying potential problems early on can prevent significant issues like fuel loss or environmental contamination. Recognizing these problems often involves careful observation of the cap’s fit, tightness, and any unusual noises or smells.

Causes of Common Gas Cap Installation Problems

Various factors can contribute to difficulties during gas cap installation. These can range from incorrect tool usage to damaged parts or improper torque application. Sometimes, seemingly insignificant details can lead to major problems. A worn or damaged gas cap gasket, for instance, will hinder a proper seal, leading to leaks.

Diagnosing and Fixing Gas Cap Installation Issues

Thorough diagnosis is essential to pinpoint the root cause of a problem. Inspect the gas cap, the threads on the gas filler neck, and the gasket for any visible damage. If damage is present, replacement is often the best course of action. A loose cap may indicate insufficient tightening, while a leak could signal a worn gasket or damaged threads.

Table of Common Gas Cap Installation Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Gas cap won’t thread onto the filler neck | Damaged threads on the filler neck or gas cap, or a foreign object lodged in the filler neck. | Inspect the filler neck and gas cap threads for damage. If damaged, replace the gas cap or filler neck. If a foreign object is present, remove it carefully. If necessary, consult a professional mechanic. |

| Gas cap leaks fuel | Faulty or worn gas cap gasket, damaged threads, or incorrect torque application. | Replace the gas cap gasket. Ensure the threads are clean and undamaged. Use the correct torque specifications to tighten the gas cap. |

| Gas cap feels loose after installation | Insufficient torque during installation, or a damaged gasket. | Re-tighten the gas cap using the correct torque specifications. If the problem persists, replace the gas cap gasket. |

| Gas cap rattles or makes unusual noises | Loose gas cap, or foreign object lodged in the filler neck. | Re-tighten the gas cap. Check for any foreign objects. If the problem persists, consult a professional mechanic. |

Maintenance and Replacement

Keeping your gas cap in tip-top shape is crucial for both the longevity of your vehicle and the safety of your fuel system. A well-maintained gas cap prevents fuel evaporation, which conserves fuel and reduces harmful emissions. Proper maintenance also minimizes the risk of leaks and potential safety hazards.Regular inspection and prompt replacement of a worn or damaged gas cap are essential steps in preventative maintenance.

This proactive approach helps maintain a sealed fuel system, which is vital for efficient fuel delivery and optimal engine performance. Ignoring these steps can lead to significant issues down the line, impacting fuel economy and potentially causing more costly repairs.

Importance of Regular Gas Cap Maintenance

Regular maintenance of your gas cap is essential for fuel system integrity. A well-maintained gas cap ensures a proper seal, preventing fuel evaporation and minimizing the risk of leaks. This not only saves fuel but also contributes to a cleaner environment by reducing harmful emissions.

Procedures for Inspecting and Replacing a Gas Cap

Inspecting your gas cap involves visually checking for any signs of damage, such as cracks, dents, or corrosion. Look for any loose or missing seals. If the cap doesn’t seem to close tightly, or if there are signs of wear, a replacement is recommended. The replacement procedure varies slightly depending on the vehicle’s make and model, but typically involves unscrewing the old cap and screwing on the new one.

Consult your owner’s manual for specific instructions tailored to your vehicle.

Signs Indicating Gas Cap Replacement

Several signs indicate that a gas cap needs replacement. A loose or poorly fitting cap is a clear indicator. You may notice a hissing sound when opening or closing the cap, which signals a leak. Corrosion or visible damage to the cap itself is another strong signal. Any unusual smells around the fuel filler area also warrant attention.

Fuel leaks are a serious concern, and immediate replacement of the gas cap is necessary.

Gas Cap Replacement Types

| Replacement Type | Procedure | Time Required |

|---|---|---|

| Standard Replacement | Unscrew the old gas cap and screw on the new one. Ensure a tight seal. | 5-10 minutes |

| Replacement with O-ring Replacement | Involves replacing the O-ring seal, which is a critical part of the cap’s sealing mechanism. Carefully remove and replace the O-ring. | 10-15 minutes |

| Replacement for vehicles with fuel system diagnostics | Some newer vehicles use diagnostic systems that can detect gas cap issues. Consult the vehicle’s owner’s manual for the specific procedure. | Variable; could be quicker or slower depending on the diagnostics. |

Properly replacing a gas cap can save you time and money in the long run. By understanding the procedures, you can maintain a safe and efficient fuel system in your vehicle.

Different Gas Cap Types and Their Application

Choosing the right gas cap isn’t just about aesthetics; it significantly impacts your vehicle’s performance and safety. Different gas cap types are designed for specific needs, and understanding their applications is crucial for maintaining optimal fuel system integrity. This section delves into the various gas cap types and their respective roles.

Standard Gas Caps

Standard gas caps are the most common type found on many vehicles. They are typically simple, relying on a sealing mechanism to prevent fuel evaporation and spills.

- Functionality: Standard gas caps offer basic protection against spills and evaporation, though not as effectively as more advanced types. They are primarily focused on preventing fuel from leaking out of the tank.

- Applications: Ideal for vehicles where fuel system integrity isn’t a primary concern or where fuel evaporation isn’t a significant issue. This is often the case with older vehicles or vehicles with smaller fuel tanks.

- Pros: Cost-effective and readily available. Simple design reduces the potential for malfunction.

- Cons: May not provide the best protection against fuel evaporation. Less effective in preventing fuel loss compared to vented or other advanced designs.

Vented Gas Caps

Vented gas caps are designed to regulate the pressure inside the fuel tank, preventing potential build-up that could lead to leaks or other issues.

- Functionality: These gas caps include a vent that allows air to enter or exit the tank as needed, maintaining a consistent pressure equilibrium.

- Applications: Vented gas caps are often recommended for vehicles with high-performance engines, as they help manage pressure fluctuations during acceleration and deceleration. They’re also useful in areas with extreme temperature variations, as they help prevent condensation.

- Pros: Reduces the risk of fuel tank pressure buildup. More effective in preventing fuel leaks, especially in certain driving conditions.

- Cons: Can sometimes lead to minor fuel vapor emissions, though usually within acceptable limits. May require more careful installation than standard caps due to the vent system.

Electronic Fuel Vapor Recovery (EVR) Gas Caps

EVR gas caps are advanced designs that capture and recycle fuel vapors, minimizing environmental impact.

- Functionality: These gas caps utilize a system to capture fuel vapors released from the tank and return them to the engine for combustion, reducing harmful emissions.

- Applications: Common on newer vehicles, especially those in regions with stricter emission standards. They are designed to significantly reduce the release of hydrocarbons into the atmosphere. Also, this system often has a valve that regulates the airflow to avoid pressure issues.

- Pros: Eco-friendly, meeting stringent emission regulations. More efficient use of fuel, which leads to minor performance gains.

- Cons: Can be more expensive than standard or vented caps. The complexity of the system may increase the likelihood of malfunction if not properly maintained.

Summary Table

| Gas Cap Type | Functionality | Applications | Pros | Cons |

|---|---|---|---|---|

| Standard | Basic sealing | Older vehicles, less demanding applications | Cost-effective, simple | Limited fuel vapor control |

| Vented | Pressure regulation | High-performance engines, varied temperatures | Reduced pressure buildup | Potential for minor emissions |

| EVR | Fuel vapor recovery | Newer vehicles, strict emission standards | Eco-friendly, efficient | More expensive, complex |

Closing Summary

In conclusion, installing a gas cap correctly is a fundamental aspect of vehicle maintenance. Following the steps Artikeld in this guide ensures your safety, prevents potential issues, and keeps your vehicle running optimally. Remember safety first, and you’ll be well on your way to a smooth and trouble-free driving experience. Happy driving!