Prime a Water Pump: Getting your water pump up and running efficiently is crucial for various applications, from residential use to large-scale operations. This guide delves into the entire process, from understanding the fundamentals to troubleshooting potential issues. We’ll cover everything from manual and automatic priming methods to safety precautions and advanced techniques for complex systems. Whether you’re a seasoned professional or a DIY enthusiast, this comprehensive guide will equip you with the knowledge and skills needed to prime a water pump effectively.

This detailed guide will walk you through the process of priming a water pump, starting with the basics and gradually progressing to more complex scenarios. Understanding the various types of pumps and their specific priming needs is essential, as is knowing how to troubleshoot common problems. We will also explore the importance of safety measures and provide valuable insights into the optimal equipment and techniques for priming your pump.

Understanding the Process

Priming a water pump is a crucial step in ensuring its efficient and reliable operation. It involves filling the pump’s internal components with water to create a pressure head and prevent air from interfering with the pump’s function. This process is essential for proper hydraulic performance, and failure to prime can lead to damage and reduced lifespan. Understanding the methods and steps involved is vital for successful pump operation.The process of priming a water pump is tailored to the specific type of pump and its intended application.

Centrifugal pumps, for instance, often require specific priming procedures, differing from those used for submersible or diaphragm pumps. By understanding these nuances, users can avoid potential issues and ensure optimal performance.

Fundamental Steps

The fundamental steps in priming a water pump typically involve creating a vacuum within the pump casing and filling it with water. This process ensures the pump operates without air pockets. The method of achieving this vacuum and introducing the water varies depending on the pump type.

Methods of Priming

Priming methods can be categorized as manual or automatic. Manual methods rely on physical actions to create the vacuum and fill the pump, while automatic methods use specialized components to facilitate the process.

- Manual Priming: Manual priming often involves using a hand pump to remove air and introduce water into the pump. This is a common method for smaller pumps and simpler setups. The operator must carefully follow the specific instructions for the pump to ensure the process is effective.

- Automatic Priming: Automatic priming systems use components like air release valves, vacuum pumps, or pressure switches. These systems are often employed for larger pumps or those requiring continuous operation, providing an automated process to avoid manual intervention.

Priming a Centrifugal Pump

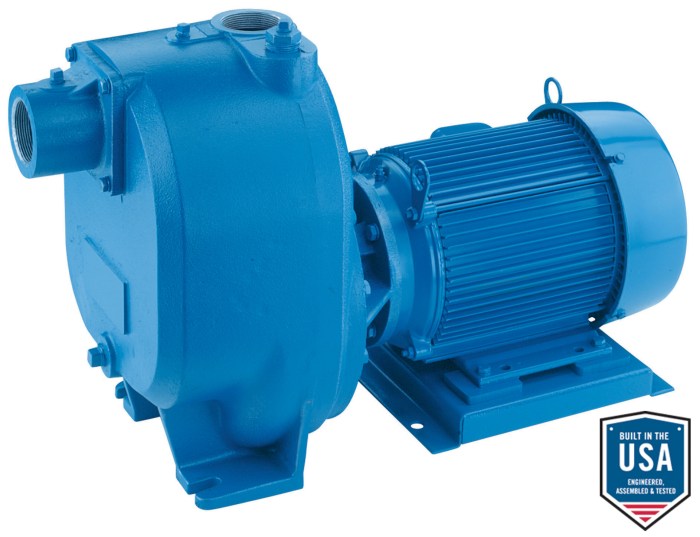

Centrifugal pumps are commonly used in various applications, from irrigation systems to industrial processes. Priming these pumps requires careful attention to the specific steps.

- Check the Pump Specifications: Consult the pump’s manual for recommended priming procedures and any specific precautions.

- Ensure the Suction Line is Clear: Verify that there are no obstructions or kinks in the suction pipe that might impede water flow.

- Fill the Suction Line: Partially fill the suction pipe with water to ensure a water seal. This step is crucial for preventing air from entering the pump.

- Remove Air Pockets: Use a hand pump or other suitable method to remove any air pockets trapped within the pump’s casing.

- Check for Leaks: Inspect the pump for any leaks or drips to ensure the priming process is effective.

- Run the Pump: Once the pump is primed, start the pump to verify its functionality.

Comparison of Priming Methods for Different Pump Types

The priming process differs significantly across pump types. Submersible pumps, for example, are designed to operate submerged in water, thus eliminating the need for explicit priming steps.

Priming a water pump can sometimes be a bit of a hassle, but it’s essential for getting your system up and running. While you’re waiting for the pump to fill with water, you might want to check out some captivating performances like watching Grizzly Bear, Beach Houses, and Victoria Legrand play a twilight song. This video might be a great distraction until your pump is ready.

Just remember to prime the pump properly afterward to avoid any further issues!

| Pump Type | Priming Method | Description |

|---|---|---|

| Centrifugal | Manual/Automatic | Manual methods use hand pumps, while automatic methods employ vacuum pumps. The pump casing is filled with water to displace air. |

| Submersible | Usually Implicit | Priming is inherent as the pump is already submerged. |

| Diaphragm | Manual/Automatic | Priming methods vary, but usually involve filling the pump casing with water and removing trapped air. |

Priming Process Flow Chart

(A visual flow chart would be included here. A flow chart is a graphical representation of a process, using shapes to depict different steps and arrows to show the sequence.)

For example:

(Start) –> Check Pump Specifications –> Ensure Suction Line is Clear –> Fill Suction Line –> Remove Air Pockets –> Check for Leaks –> Run Pump –> (End)

Troubleshooting Priming Issues

Getting a water pump primed correctly is crucial for its efficient and reliable operation. A pump that struggles to prime can lead to wasted energy, potential damage, and frustrating delays. Understanding the common causes of priming issues and how to diagnose them will empower you to maintain and repair your water pump effectively.Pump priming failure is often rooted in the presence of air pockets within the system.

Air, being compressible, disrupts the flow of water, creating resistance and preventing the pump from building the necessary pressure for proper operation. Addressing these air pockets is paramount to restoring the pump’s functionality.

Priming a water pump can be a bit of a hassle, but it’s essential for getting things flowing. Speaking of things flowing, did you know there are various types of lip piercings? Exploring the different styles, like the philtrum piercing or the cupid’s bow piercing, Types of Lip Piercings is a great resource to learn more.

Once you’ve got a handle on the different options, you can get back to ensuring your pump is primed and ready to go.

Common Causes of Priming Problems

Air pockets within the pump system are a frequent culprit in priming issues. Various factors contribute to this buildup of air. Understanding these causes allows for targeted solutions.

- Air leaks in the pump assembly:

- Leaks at the pump’s suction hose connections or fittings can allow air to enter the system. This is often the case when hoses or fittings are not properly secured, or if they are worn or damaged. Inspect all connections for any visible leaks or signs of damage.

- Air leaks from the pump itself:

- Faulty seals or gaskets within the pump’s internal components can create air leaks. Wear and tear, or improper installation can lead to these issues. Regular maintenance and inspection are critical to identify such issues early.

- Insufficient suction head:

- The suction head refers to the vertical distance the pump must lift water. If this distance is too great, the pump may struggle to overcome the atmospheric pressure and draw water, leading to priming failure. A properly sized pump for the application and elevation is vital. For example, a pump rated for 20 feet of suction head will likely struggle to prime a well over 30 feet deep.

Diagnosing Air Leaks

Pinpointing the exact source of air leaks is key to effective repair. Careful inspection and methodical troubleshooting are crucial.

- Visual Inspection:

- Inspect all connections, hoses, and fittings for any visible leaks. Pay attention to signs of damage, such as cracks, tears, or loose connections. A soapy water solution can help identify subtle leaks that might not be immediately apparent.

- Listening for Air Leaks:

- Listen carefully for hissing or bubbling sounds around the pump’s components. This can indicate an air leak in a specific location. A stethoscope can help pinpoint the source of the sound.

Addressing Insufficient Suction Head

Pump selection is critical in preventing priming issues stemming from insufficient suction head.

- Pump Selection:

- Choose a pump with a sufficient suction head capacity to meet the required elevation difference. Refer to the pump’s specifications to ensure it is suitable for the height difference between the water source and the pump’s intake. A pump that’s too small for the job will struggle to prime the system.

- Check for Obstructions:

- Ensure the suction line is clear of any obstructions, such as debris or kinks. A clear suction line is vital for optimal water flow. Thorough cleaning of the suction line can resolve this issue.

Inspecting for Wear and Tear

Regular maintenance is key to preventing priming problems caused by wear and tear.

- Seal Inspection:

- Inspect the seals and gaskets within the pump’s internal components for signs of wear or damage. Faulty seals can allow air to enter the system, hindering priming. Replace worn seals to maintain optimal performance.

- Component Inspection:

- Examine the pump’s internal components for any damage or signs of corrosion. Corrosion and damage can affect the pump’s ability to draw water, affecting priming. Thorough inspection can reveal problems early.

Equipment and Materials

Getting a water pump primed successfully often hinges on the right tools and equipment. Proper selection and use of these items significantly impact the priming process, reducing potential issues and ensuring a smooth operation. This section details the essential equipment needed for successful priming, along with a deeper look into various types of priming devices, hoses, valves, and a comparison of priming techniques.Priming a water pump is not just about getting the pump working; it’s about ensuring the pump operates efficiently and reliably.

The right equipment can prevent costly repairs and ensure the pump lasts longer. Careful consideration of each component, from the priming device to the suction hose, is crucial for a successful priming process.

Essential Equipment for Priming

Proper priming requires a collection of essential tools. This equipment ensures a controlled and effective priming procedure, avoiding issues that might arise from insufficient or inappropriate tools. The key equipment needed for priming a water pump includes:

- A priming device (such as a pump or a hand-operated priming tool).

- A suction hose of suitable length and material.

- A water source (well, tank, or reservoir).

- Valves (check valves, shut-off valves) for controlling water flow.

- Appropriate safety gear (gloves, eye protection).

Types of Priming Devices

Different priming devices cater to various applications and pump types. Understanding their specific characteristics helps in choosing the most appropriate device for the job.

| Priming Device Type | Description | Applications |

|---|---|---|

| Manual Priming Pump | A hand-operated pump that creates suction. | Small pumps, temporary applications, and pumps with limited suction lift. |

| Electric Priming Pump | An electrically powered pump that generates higher suction pressures. | Larger pumps, applications requiring higher flow rates, and longer suction runs. |

| Air-Powered Priming Pump | A pump that utilizes compressed air to prime the water pump. | Applications requiring quick priming, and situations where electrical power is unavailable. |

Suction Hoses and Their Characteristics

The suction hose plays a critical role in the priming process. Its characteristics significantly impact the efficiency and success of priming.

- Material: A smooth, non-porous material like PVC or rubber is ideal for minimizing friction and air entrapment.

- Length: The length should be appropriate for the distance between the water source and the pump, with consideration for elevation differences. A shorter hose is generally better for shorter suction distances, and longer hoses may require additional assistance, like a priming pump. For longer runs, a more robust priming device might be necessary.

- Diameter: A larger diameter hose reduces friction, aiding in the smooth flow of water.

- Flexibility: A flexible hose makes routing around obstacles easier, allowing for greater maneuverability. This is important for various installations.

Valves and Their Use During Priming

Valves play a crucial role in controlling water flow during the priming process. They ensure that water flows efficiently and safely through the system.

- Check Valves: Prevent backflow, ensuring that water doesn’t flow back from the pump to the water source.

- Shut-off Valves: Enable the isolation of sections of the plumbing system during priming and maintenance, enabling precise control over water flow.

Comparison of Priming Techniques

Different priming techniques offer varying degrees of effectiveness and efficiency. Choosing the appropriate technique depends on the specific pump and application.

| Priming Technique | Description | Effectiveness |

|---|---|---|

| Manual Priming | Using a hand-operated pump to create suction. | Effective for smaller pumps and short suction runs. |

| Air Priming | Utilizing compressed air to remove air pockets. | Efficient for pumps with longer suction lines or in situations where electrical power is unavailable. |

| Vacuum Priming | Using a vacuum pump to create a negative pressure. | Effective for pumps with high suction lift requirements. |

Safety Precautions

Priming a water pump, while seemingly straightforward, involves potential hazards if safety protocols aren’t meticulously followed. Understanding and adhering to safety precautions is paramount to preventing accidents and ensuring a smooth, risk-free priming procedure. This section details essential safety measures to protect personnel and equipment during the priming process.Working with pressurized systems inherently carries risks. Improper handling can lead to accidental discharges of water or other fluids, causing injury or property damage.

Furthermore, high-pressure situations necessitate extreme caution to avoid equipment malfunctions and associated dangers.

Pressurized System Risks

Pressurized systems, like those in water pumps, can cause significant harm if not handled correctly. Sudden pressure releases can lead to forceful water jets, potentially causing cuts, bruises, or more severe injuries. Proper handling and safety gear are essential to minimize these risks. Always use appropriate safety glasses and protective clothing.

Grounding and Electrical Safety

Electrical components are often integral to water pump systems. Improper grounding can lead to electrical shocks, while faulty wiring or connections can cause fires. Ensuring proper grounding and electrical safety measures are crucial. Always verify that the pump’s electrical connections are secure and compliant with local electrical codes. Never work on electrical components if you’re not properly trained and equipped with the appropriate safety gear.

Safety Checklist for Priming

A comprehensive safety checklist helps to systematically address potential hazards and minimize risks.

Priming a water pump is crucial for efficient operation, especially in agricultural settings. This process, like so many things, is all about getting things started. Just like the talented musicians in the new Macklemore & Ryan Lewis album, featuring Chance the Rapper, Anderson .Paak, YG, KRS-One, DJ Premier, Idris Elba, and more, (check out the details here ) the right priming ensures a smooth, powerful flow.

Ultimately, priming a water pump is all about preparing for peak performance.

- Inspect the pump and surrounding area for any visible hazards, such as debris or obstructions.

- Ensure all necessary safety equipment, including safety glasses, gloves, and appropriate footwear, is readily available and worn.

- Turn off the power supply to the pump before performing any maintenance or priming activities.

- Disconnect the water supply line to prevent accidental water discharge.

- If using specialized tools, ensure they are in good working order and suitable for the task.

- When working with pressurized systems, use caution and follow all manufacturer’s instructions carefully.

- Never attempt to prime a pump without proper training and supervision.

Improper Priming Tool Hazards

Using inadequate or damaged priming tools can lead to several safety concerns. Improper tools may malfunction, leading to equipment damage or injury. For example, a cracked or damaged priming tube can rupture under pressure, causing water to spray unexpectedly. Similarly, a poorly designed priming tool might not provide sufficient suction, leading to extended priming time and increased strain on the pump.

Using appropriate and well-maintained tools is crucial to prevent such risks.

Example of a Potential Hazard

Imagine a scenario where a worker attempts to prime a pump using a damaged priming hose. The hose, weakened by previous use, ruptures under pressure, causing a forceful spray of water. The worker, not wearing safety glasses, is hit in the face by the water spray, resulting in a serious eye injury. This incident highlights the importance of using only certified and well-maintained tools, coupled with the proper use of safety equipment.

Applications and Examples

Getting a water pump primed correctly is crucial for its efficient operation and longevity. Different applications demand specific priming techniques and pump types. Understanding these applications will help you choose the right pump and ensure optimal performance. Proper priming is vital to avoid damage and ensure a smooth water flow, especially in critical settings like construction or agriculture.This section explores real-world applications of water pumps, highlighting the importance of priming and the different types of pumps used in various scenarios.

It will also showcase how priming impacts pump performance in diverse conditions.

Real-World Examples of Priming

Priming is essential in various settings. Construction sites often utilize submersible pumps to move water from excavation sites or temporary ponds. These pumps need priming to start moving water efficiently. In agricultural settings, centrifugal pumps are frequently used for irrigation. Proper priming ensures the pump can handle the water flow required for crops.

Similarly, in industrial applications, priming is critical for maintaining continuous water supply.

Scenarios Requiring Priming

Priming is necessary whenever a pump is situated above the water source or in situations where air pockets can form within the pump’s suction line. These scenarios include:

- High-elevation water transfer: In mountainous areas, pumps must lift water from lower elevations. The pumps need priming to create the initial pressure and draw water upwards. This is common in rural water systems.

- Deep well pumping: Submersible pumps in deep wells need priming to overcome the pressure difference and create a vacuum to draw water from the well. Without priming, the pump will not operate effectively.

- Pumping from a tank or reservoir: When water is being drawn from a reservoir or tank located above the pump’s intake, priming is necessary to create the initial pressure difference. Pumps used in these scenarios often require a priming method to ensure the pump draws the water properly.

Pump Types and Priming Methods

The following table illustrates various applications of water pumps and the priming methods employed in each. Understanding the relationship between the pump type and the necessary priming method is crucial for optimal performance.

| Application | Pump Type | Priming Method |

|---|---|---|

| Irrigation | Centrifugal pumps | Manual priming or using a priming tank/device. |

| Construction site water removal | Submersible pumps | Self-priming or manual priming using a vacuum source. |

| Residential water supply | Shallow well pumps | Manual priming using a hand pump or a priming device. |

| Industrial water transfer | Vertical turbine pumps | Priming is often a complex process, requiring specialized equipment and procedures. |

Impact of Priming on Pump Performance

Proper priming ensures a smooth start-up, prevents cavitation, and optimizes the pump’s performance. Without priming, the pump might not draw water effectively, resulting in reduced output or even damage to the pump. This is especially critical in high-pressure applications.

“Adequate priming is essential to avoid cavitation, which can damage pump components.”

Furthermore, improper priming can lead to reduced efficiency, higher energy consumption, and potential pump failures.

Pump Types and Priming Requirements

The table below highlights the typical priming requirements for different pump types. It is essential to understand these requirements for effective operation and maintenance.

| Pump Type | Typical Priming Requirements |

|---|---|

| Centrifugal pumps | Manual priming, priming tank, or a vacuum source may be needed depending on the specific design. |

| Submersible pumps | Self-priming design is common; however, some situations may require external priming devices. |

| Vertical turbine pumps | Often require specialized priming methods, sometimes involving a priming tank or a vacuum pump. |

Advanced Techniques and Considerations

Priming a water pump can be straightforward for simple systems, but complex setups require advanced techniques to ensure efficient and reliable operation. Understanding these techniques is crucial for preventing costly downtime and ensuring optimal performance. This section dives into advanced priming methods, considering factors like pump size, system characteristics, and the use of specialized equipment.Pumping systems vary greatly in complexity, from simple domestic systems to intricate industrial installations.

Advanced techniques are necessary to prime these diverse setups effectively. Factors like suction head, pipe length, and the presence of air pockets significantly impact the priming process. This section will cover the necessary strategies to overcome these challenges.

Advanced Priming Techniques for Complex Pumping Systems

Various techniques can enhance the priming process for complex pumping systems. These techniques often involve combining traditional methods with specialized equipment. The goal is to efficiently remove air from the system and create a continuous flow.

- Using vacuum pumps to accelerate the priming process is a common approach in complex systems with long suction lines or significant elevation differences. Vacuum pumps create a lower pressure environment, facilitating the removal of air and the quicker establishment of a liquid column.

- In situations with multiple pumps in series or parallel, careful consideration must be given to the priming sequence. Priming one pump before the other can prevent air lock issues. Proper coordination is crucial for optimal performance.

- Employing a priming tank can be a critical component for ensuring uninterrupted operation in complex systems, particularly those with fluctuating flow demands. A priming tank acts as a reservoir, maintaining a continuous supply of liquid for the pump even when the main water source is interrupted.

Vacuum Pumps in Priming

Vacuum pumps are instrumental in overcoming priming challenges in various pumping systems. They effectively remove air pockets and speed up the priming process, which is especially beneficial in systems with long suction lines or high suction lifts.

- Vacuum pumps work by creating a vacuum, drawing air out of the system. This creates a pressure differential that facilitates the flow of liquid into the pump.

- Choosing the appropriate vacuum pump is crucial; the pump’s capacity should match the system’s air volume to be removed efficiently. Consider the pump’s maximum vacuum pressure and pumping rate to ensure compatibility.

- Vacuum pumps are often used in conjunction with other priming methods, such as air vents or priming tanks. This combination enhances the effectiveness of the priming process, leading to faster and more reliable results.

Impact of Pump Size and Type on Priming

The size and type of the pump significantly influence the priming process. Different pumps have varying capabilities and priming characteristics.

- Larger pumps, typically used in industrial applications, may have longer priming times compared to smaller pumps due to the larger volume of liquid that needs to be drawn into the system.

- Centrifugal pumps, a common type, rely on impeller rotation to create suction. The impeller’s design and speed affect the priming efficiency. High-speed impellers generally prime faster.

- Pumps with larger suction openings typically prime faster than pumps with smaller openings, allowing for a more rapid filling of the pump chamber.

Priming Time Variation Based on System Characteristics

The priming time is a crucial factor that depends on several characteristics of the system. Several factors can influence priming time, such as the pump’s characteristics and the specific configuration of the system.

- The length of the suction pipe directly impacts the priming time. Longer pipes require more time to fill with liquid and to overcome the air resistance. This is due to the increased friction and the larger volume of air to be displaced.

- The elevation difference between the water source and the pump, known as the suction head, affects the priming time. Higher suction heads require more effort to overcome the gravitational pull, thus leading to longer priming periods.

- The presence of air pockets in the suction pipe and the pump chamber can significantly increase the priming time. Removing these air pockets is essential for efficient priming.

Pump and System Curves in Priming

Pump curves and system curves are essential tools for determining the priming requirements of a system. Understanding these curves helps predict the system’s behavior during priming.

Pump curves display the pump’s performance characteristics, showing the relationship between flow rate and head. System curves illustrate the system’s resistance to flow, reflecting the total head required by the piping system and other components.

- A critical aspect is determining the operating point where the pump curve intersects the system curve. This intersection point indicates the flow rate and head at which the pump will operate. Understanding this point is vital to avoid priming issues.

- Analyzing the curves can reveal potential priming challenges, such as insufficient suction head, which can result in air entrapment in the system. These insights help in selecting the appropriate pump and designing an effective priming strategy.

- Pump curves and system curves provide valuable insights into the pump’s ability to overcome the system’s resistance during the priming phase. This analysis ensures that the pump has sufficient capacity to prime the system effectively.

Illustrative Examples: Prime A Water Pump

Priming a water pump is a crucial step in ensuring efficient and reliable water delivery. Proper priming, a process of removing air from the pump’s piping and creating a vacuum, is vital for optimal performance and prevents potential damage to the equipment. Understanding the specific scenarios and steps involved in priming various pump types is essential for successful operation.

Submersible Well Pump Priming

Submersible well pumps, often used for residential water supply, are typically more challenging to prime than surface pumps due to their location in the well. The water level within the well needs to be high enough to draw water up the piping. Several factors influence the priming process, including well depth, water level, and pump design.

- Initial Assessment: Before starting the priming process, it is essential to verify that the well casing is sound and properly sealed. Also, ensure the pump is correctly installed in the well and that the electrical connections are secure and correctly grounded. Water levels in the well should be checked and recorded, and the pump’s suction pipe must be adequately sized and clear of obstructions.

- Pumping Process: The pump is usually started, and the water level in the well should start to rise. If there is a significant delay or no water flow, there could be air in the pump or piping. The pump should be run for a predetermined time to establish water flow and eliminate air pockets.

- Monitoring and Adjustments: Regular monitoring of the water level and flow rate is crucial. If the water level doesn’t rise or the flow is weak, the pump’s settings should be adjusted to ensure optimal performance.

Residential Water Pump Priming

Priming a water pump for a residential application typically involves a surface pump situated above the water source. The process is often simpler than for submersible pumps.

- Filling the Suction Line: The first step is to fill the pump’s suction line completely with water. This ensures there are no air pockets hindering the pump’s operation. The pump should be positioned such that the suction line is below the water level.

- Starting the Pump: Once the suction line is filled, the pump can be turned on. A steady flow of water should be observed, indicating that the priming process is complete. If the pump struggles to prime, check for any blockages in the suction line.

- System Testing: After the pump is operational, run the system to test the flow rate and pressure. This ensures the pump is performing efficiently and supplying the required water pressure.

Pump Priming Failure Case Study

A pump installed in a new residential home failed to prime. The suction line was correctly sized and below the water level, but the pump remained dry.

- Troubleshooting Steps:

- Inspecting the suction line for blockages or kinks.

- Checking the water level in the supply tank or reservoir.

- Ensuring the pump’s electrical connections were secure and correct.

- Verifying the pump was installed properly.

The issue was a kink in the suction pipe that wasn’t immediately apparent during the initial installation. Once the kink was rectified, the pump primed successfully.

Fire Pump Priming

Fire pumps are designed for high-pressure water delivery and are often used in emergency situations. Priming a fire pump is crucial for ensuring rapid and effective water flow.

- Specialized Design: Fire pumps typically utilize a priming device, which is a dedicated component to fill the suction line with water, creating the initial vacuum for the pump to draw water. This is crucial to ensure rapid water delivery when time is critical.

- Manual Priming Procedure: If the priming device malfunctions, a manual priming procedure is typically followed. This usually involves filling the suction line with water by hand or using a hose.

- Testing and Verification: After priming, the pump’s performance should be tested to ensure the water flow is adequate and pressure is sufficient. This is essential to confirm the pump’s readiness for emergency situations.

Visual Representation

Visual representations are crucial for understanding complex processes like pump priming. They provide a clear, concise, and easily digestible way to visualize the steps involved, making the entire procedure more accessible and less intimidating. This section will present various diagrams to illustrate the priming process and related concepts.

Centrifugal Pump Priming Diagram

This diagram illustrates the priming process for a centrifugal pump. A centrifugal pump relies on the impeller’s rotation to create pressure and move the liquid. Priming is essential to ensure the impeller is submerged in the liquid, allowing for proper operation. The diagram shows the pump with the suction pipe submerged in the liquid reservoir. The impeller is shown within the pump casing, and the process of liquid filling the pump casing and being pushed through the discharge pipe is depicted.

Proper priming ensures a continuous flow of liquid into the pump.

Components of a Priming System

A well-designed priming system includes several critical components. Understanding these components and their functions is vital for successful priming. This diagram displays the key components of a priming system. The diagram shows the reservoir, the suction pipe, the pump, the discharge pipe, and the priming mechanism. Each component plays a specific role in the priming process, from supplying the liquid to delivering it to the desired destination.

Manual vs. Automatic Priming Methods

Manual priming requires direct intervention, while automatic priming systems operate independently. The difference is crucial for understanding pump operation and maintenance needs. This diagram visually contrasts manual and automatic priming methods. Manual priming typically involves filling the pump casing with a liquid using a manual valve or a hand-operated device. Automatic priming systems employ pumps or other mechanisms to ensure the pump is filled without operator intervention.

Typical Priming Setup Schematic, Prime a Water Pump

A typical priming setup consists of interconnected components working together to achieve successful priming. The schematic diagram represents a typical priming setup. The diagram shows the piping arrangement, valves, and other crucial components, including a pressure gauge to monitor the system’s performance.

Troubleshooting Flowchart for Non-Priming Pumps

A flowchart provides a structured approach to diagnosing and resolving priming issues. This structured troubleshooting approach is critical in quickly identifying the root cause of pump failure. The flowchart illustrates the steps to follow when a pump fails to prime. It guides users through checking the suction head, the presence of air in the lines, and other critical parameters to pinpoint the cause of the problem.

Each step is designed to help the user isolate the issue efficiently.

Concluding Remarks

In conclusion, priming a water pump, whether for a simple residential application or a complex industrial setup, requires careful attention to detail and adherence to safety protocols. This guide has provided a comprehensive overview of the entire process, from understanding the fundamental steps to troubleshooting common issues. By following the provided techniques, you can ensure your pump is primed efficiently and safely, maximizing its performance and longevity.

Remember to prioritize safety throughout the entire process.